Our modular watermaker combines high-quality components with a rugged design, ensuring reliability. Designed for simplicity, our watermakers are free of complex electronics, making them easy to use and maintain — no tedious troubleshooting or worrying about fragile parts. With high output capacity, you’ll have plenty of fresh water to fuel your adventures, whether you’re on a coastal trip or a grand voyage.

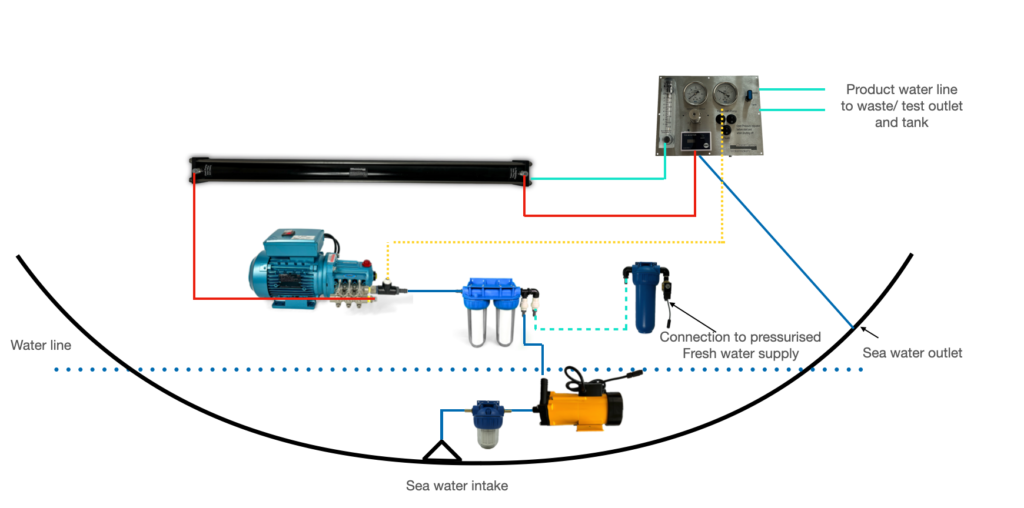

Installation is a breeze with our plug-and-play setup, allowing you to get up and running in no time. Plus, our customizing options ensure the system is tailored to fit your unique needs.

Quality, simplicity, and reliability — just what every sailor needs.

Learn all about our systems below.

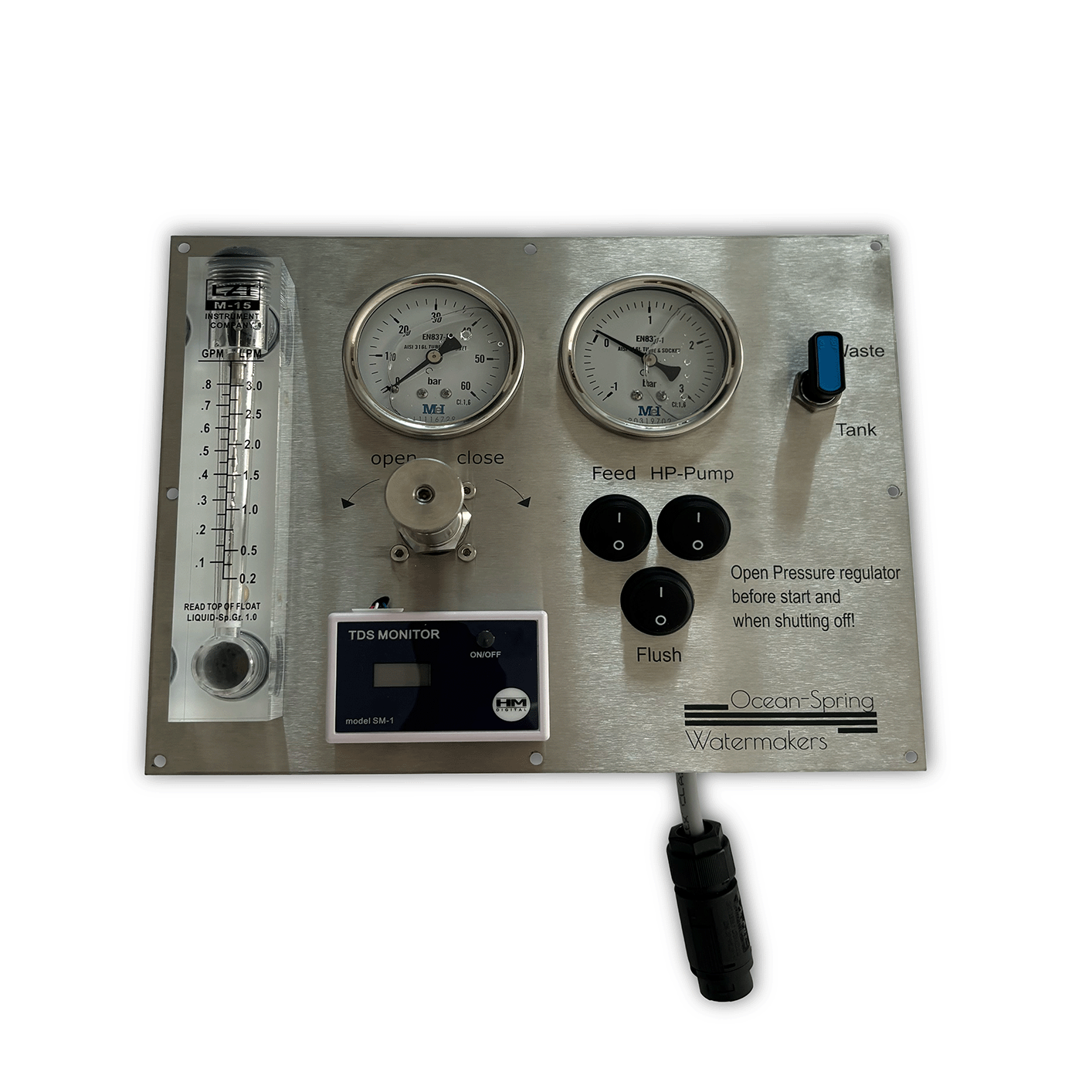

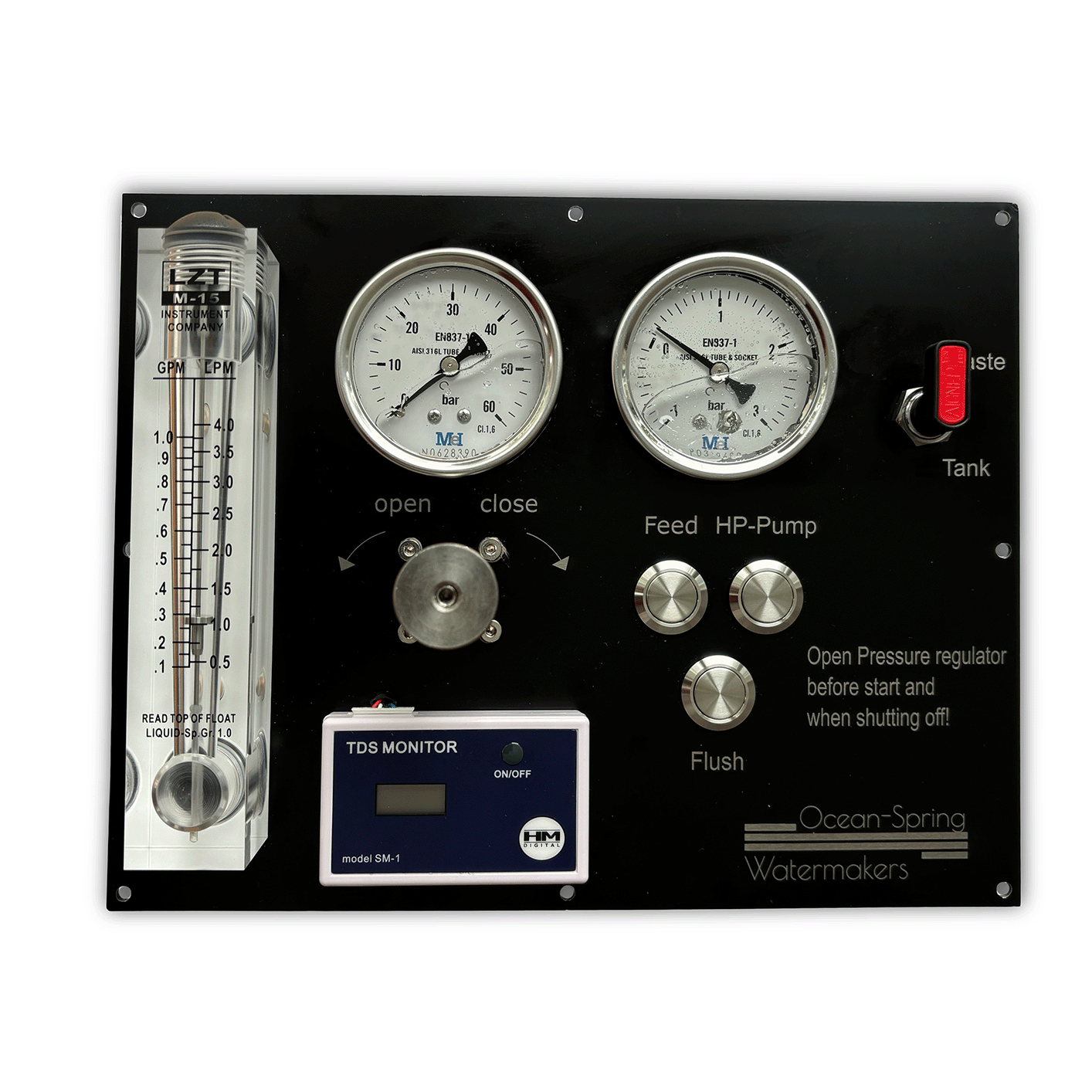

By standard, we deliver our modular watermakers with a stainless steel control panel. All operational processes can be carried out on the control panel, which significantly increases the comfort of use.

Our specially manufactured pressure regulator works with a spring and can thus compensate for flow fluctuations. The result is a very constant operating pressure, which can also be adjusted easily and in a short matter of time.

On request, a compact version without product water control can also be offered. Also automated product water control can be added to such a panel separately.

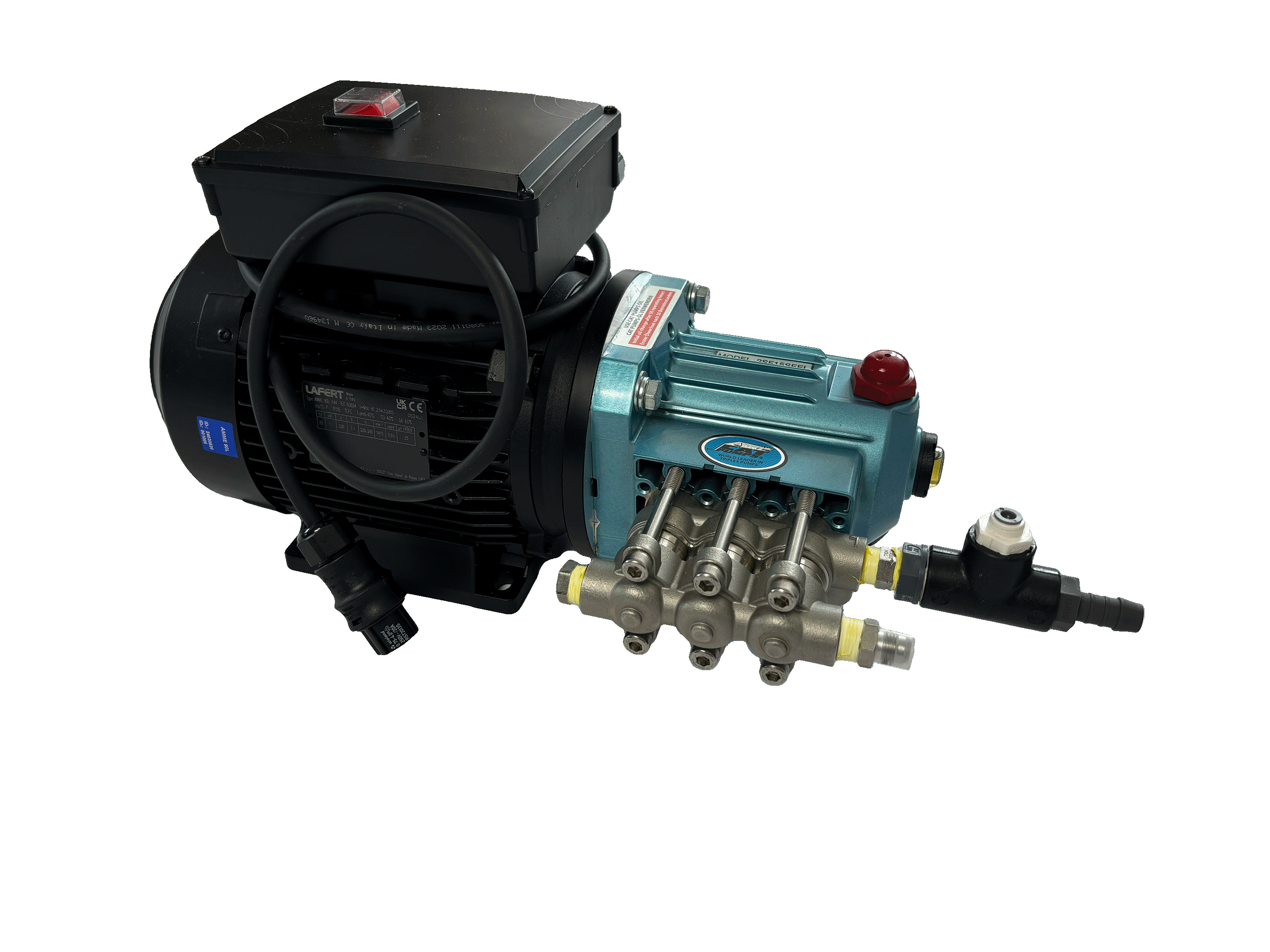

One of the two core pieces of a conventional watermaker is the high-pressure pump. It is the most expensive individual component and usually determines the longevity and reliability of the system.

Reason enough not to make any compromises here. Cat Pumps is one of the market leaders in the industrial high-pressure pump segment and one of the few manufacturers that have proven themselves over the years.

The second core piece – the membrane. This is where the actual desalination takes place. In addition to the pure performance data of the membrane, which are decisive for the salinity of the product water and the specific energy consumption of the system, the manufacturing quality also determines the mechanical strength of the membrane and thus its longevity. Among the many manufacturers in the reverse osmosis membrane market, Dupont stands out for its outstanding performance and durability.

Reason enough for us not to go cheap here and to focus on quality. Of course in standard sizes, which can be easily replaced anywhere in the world if in doubt.

To house the membrane we make our own membrane housings allowing for a very simple and compact installation. All of our tubes are pressure tested and except for the fittings (316) there is no metal in contact with the sea water. So there is no reason to worry about corrosion.

We deliver our watermakers complete with all the materials you need for the installation.

In most cases, you don’t need to provide anything other than suitable surfaces for installation and through holes in order to be able to connect and operate your Watermaker. We also offer accessories for connecting the product water to your tanks – everything from a single point of contact!

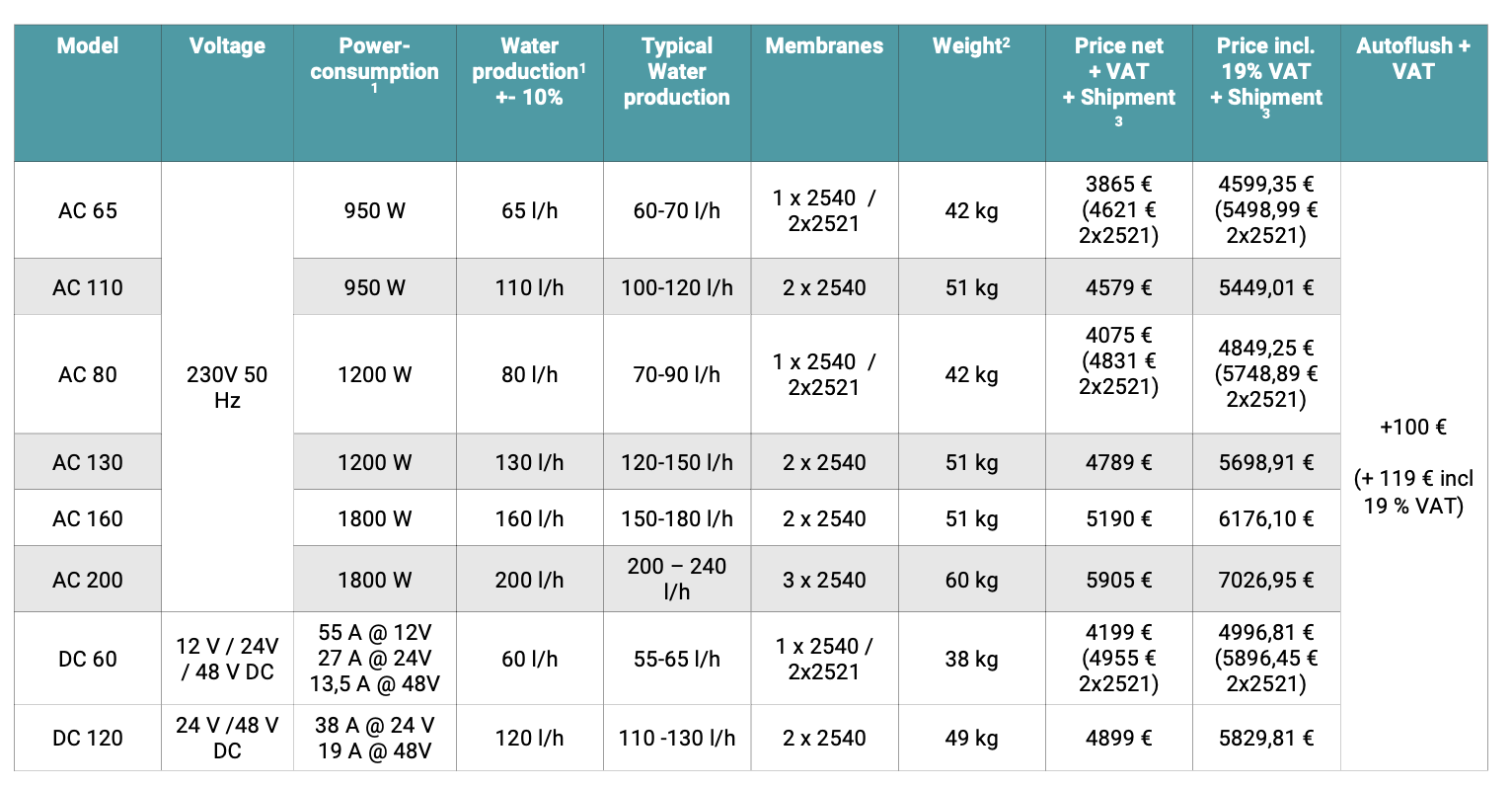

1: Values based on 3,5% Salinity, 55 bar operational pressure and 25°C Feed water temperature

2: Weights based on dry systems & excl hoses.

3: VAT rate of your delivery country is to be applied. Final prices in shop might differ accordingly. + Shipment cost

All our listed models are usually available from stock within 5 days. 48V Versions are only made upon request and require a longer lead time of about 4 weeks.

You can find all our models here in the Shop.